Product Details

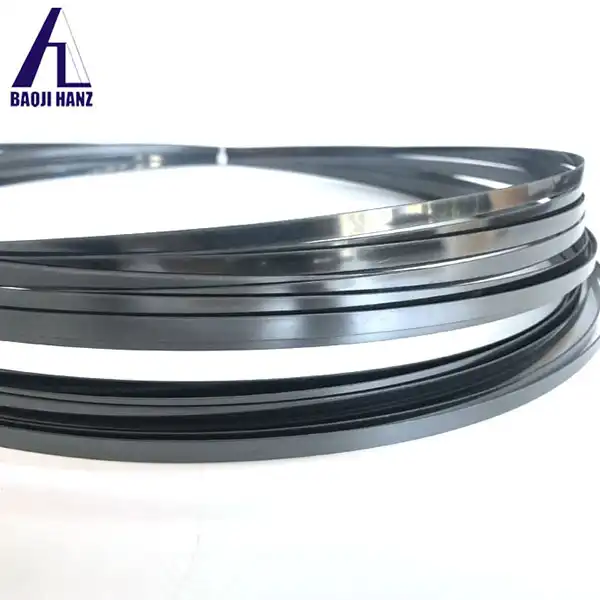

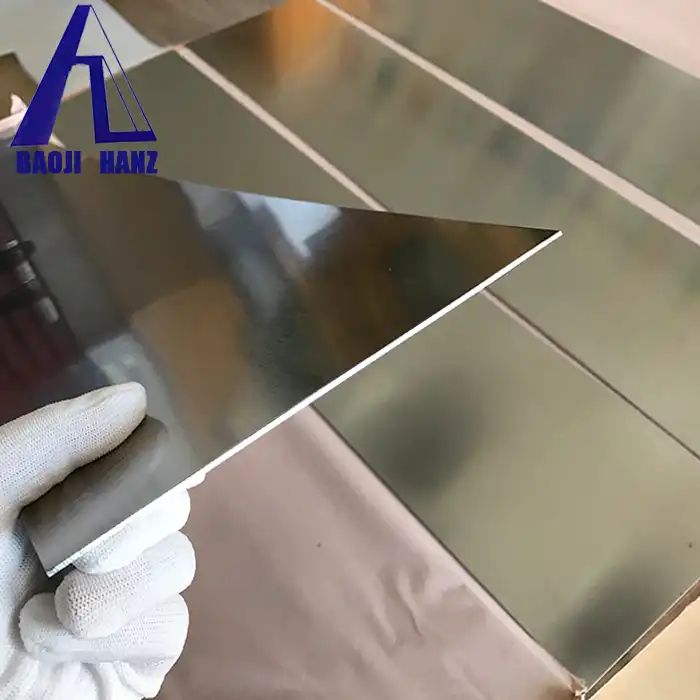

Shape Memory Alloy (SMA) Nitinol flat wire is a high-performance material renowned for its unique shape memory and superelastic properties. Comprising nickel and titanium, this alloy exhibits the ability to return to its pre-defined shape upon heating after deformation, a phenomenon known as the shape memory effect. Additionally, it displays superelasticity, allowing it to undergo significant strain and recover its original form without permanent deformation. These characteristics make Nitinol flat wire an essential material in various demanding applications.

Our Nitinol flat wire is available in a range of dimensions and thicknesses to meet diverse industrial requirements. It is meticulously manufactured and subjected to rigorous quality control measures to ensure high consistency and performance. The wire's excellent biocompatibility makes it suitable for medical applications, while its corrosion resistance ensures durability in harsh environments. Whether used in medical devices, robotics, or aerospace components, Nitinol flat wire offers exceptional reliability and functionality.

Specifications

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Black, brown, brown, blue, bright |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Wire Gauge | 0.02mm min |

| Tensile strength | 980 Mpa |

| Feature | Shape memory |

| Supply Status | Full annealed |

| Modulus of elasticity | Austenite 83 Gpa |

| The Max recovery stress | 185 MPa |

| Standard | ASTM F2063, Q/XB1516 |

| Certificate | ISO9001:2015 |

| Application | Guide wires Shape set parts ,Orthodontic Files .Arch wire . fishing wire .bra frames wire .glasses wire .spring wire |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| The production certification | ||||||

| Specification (mm) | Shape Memory Nitinol wire | Typical Medical industry Application | ||||

| UTS (Mpa) | Elongation % | UpperPlateau Stress Mpa | Permanent Set after 6% strain % | Active AF | ||

| 0.1-0.3mm | ≥1100 | ≥15 | ≥480 | <0.5 | Subzero20~100 | Guide wires Shape set parts, orthodontic files, arch wire, fishing wire, bra frames wire, glasses wire,spring wire |

| 0.3~0.6mm | ≥920 | ≥15 | ≥440 | <0.5 | ||

| 0.6~3.0mm | ≥850 | ≥15 | ≥440 | <0.5 | ||

|

|

|

Application Areas

Medical Devices: Nitinol flat wire is widely used in the medical industry due to its biocompatibility and unique mechanical properties. It is commonly employed in stents, guidewires, and dental braces. The wire's ability to change shape in response to temperature changes makes it ideal for minimally invasive surgical tools that can navigate the human body’s complex pathways and then return to a desired shape for therapeutic purposes.

Aerospace: In the aerospace sector, Nitinol flat wire is valued for its high strength-to-weight ratio and superelastic properties. It is used in actuators and components that need to withstand extreme temperature variations and mechanical stress. The material's ability to revert to its original form ensures reliable performance in critical applications.

Robotics and Automation: The flexibility and resilience of Nitinol flat wire make it an excellent choice for robotics. It is used in robotic actuators, sensors, and flexible joints. Its superelasticity allows robots to perform intricate movements and adapt to various tasks without suffering permanent deformation, thereby enhancing the durability and functionality of robotic systems.

Consumer Electronics: In consumer electronics, Nitinol flat wire is utilized for making flexible connectors, foldable screens, and other components that benefit from its durability and ability to recover from bending or twisting. Its application in wearable technology is also gaining traction due to its lightweight and biocompatible nature.

Automotive Industry: The automotive industry leverages Nitinol flat wire for various applications, including adaptive control systems and sensors. The material’s ability to endure repeated deformation and recover its shape improves the reliability and longevity of automotive components.

Features

Shape Memory: Returns to pre-defined shape upon heating.

Superelasticity: Recovers original shape after deformation.

Biocompatibility: Safe for use in medical devices.

Corrosion Resistance: Withstands harsh environments.

High Strength-to-Weight Ratio: Strong yet lightweight material.

Production Technology

The production of Nitinol flat wire involves advanced manufacturing techniques to ensure the highest quality and performance. The process begins with vacuum induction melting to achieve a homogenous composition. The alloy is then subjected to precise rolling and annealing processes to obtain the desired dimensions and mechanical properties. Each batch undergoes thorough testing to verify its chemical composition, tensile strength, and superelastic characteristics, ensuring that the final product meets stringent industry standards.

Quality Control

Quality control is an integral part of our manufacturing process. We implement rigorous testing protocols at every stage of production to ensure the Nitinol flat wire meets all specifications. This includes chemical analysis, mechanical testing, and thermal cycling tests to confirm the shape memory effect and superelastic properties. Our commitment to quality ensures that every product delivers consistent performance and reliability.

Nitinol Production Process&Shipping

FAQs

Q: What is Nitinol flat wire primarily used for? A: Nitinol flat wire is used in medical devices, aerospace components, robotics, consumer electronics, and automotive applications due to its shape memory and superelastic properties.

Q: Is Nitinol flat wire biocompatible? A: Yes, it is biocompatible, making it suitable for medical implants and devices.

Q: What is the typical composition of Nitinol? A: Nitinol typically consists of 55-56% nickel and the balance titanium.

Q: How does the shape memory effect work? A: The shape memory effect allows the wire to return to its original shape when heated after being deformed.

Q: What are the benefits of using Nitinol in robotics? A: Nitinol offers flexibility, resilience, and superelasticity, which are crucial for robotic components that require precise and reliable movements.

Final Details

Baoji Hanz Metal Material Co., Ltd. is a professional manufacturer and supplier of Shape Memory Alloy Nitinol flat wire. We offer a large inventory, complete certifications, and fast delivery to meet your needs. For any inquiries or to choose your own nickel-titanium wire, please contact us at baojihanz-niti@hanztech.cn. Our dedication to quality and customer satisfaction ensures that you receive the best products and services available.

This content is professionally prepared for buyers and global dealers, ensuring clarity and ease of understanding.

Send Inquiry

.webp)

.webp)