Baoji Hanz Metal Material Co., Ltd.: Your Trusted Nickel Titanium Wire Manufacturer & Supplier

Nickel Titanium wire, commonly referred to as Nitinol wire, is a unique metal alloy composed of nickel and titanium, typically in near-equal proportions. Known for its extraordinary shape memory and superelastic properties, Nitinol wire has become an essential material in various high-tech industries, particularly in medical devices, aerospace, and robotics. Baoji Hanz Metal Material Co., Ltd. offers premium quality it that meets rigorous industry standards, with customizable specifications to suit diverse applications. With a strong reputation as a reliable manufacturer and supplier, we ensure our products maintain top-notch quality, performance, and durability.

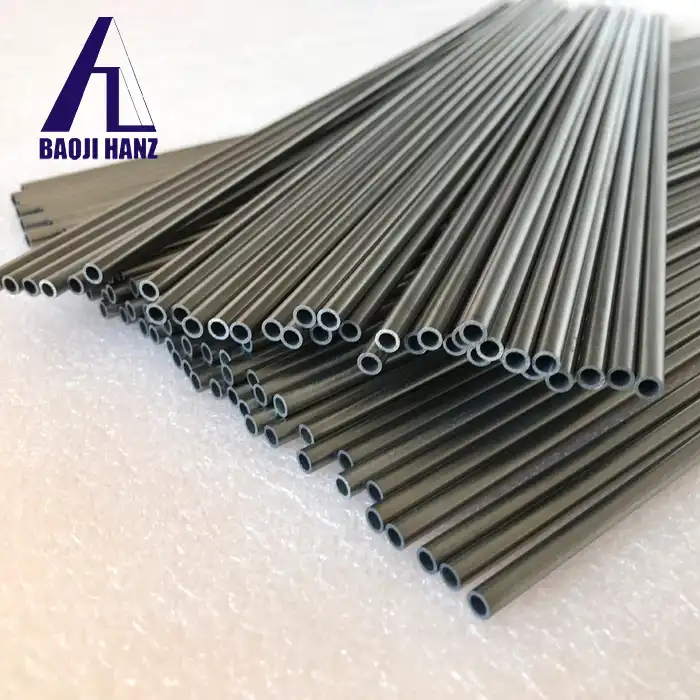

Nickel Titanium Wire Specifications

| Specification | Details |

|---|---|

| Diameter Range | 0.03mm to 5.00mm |

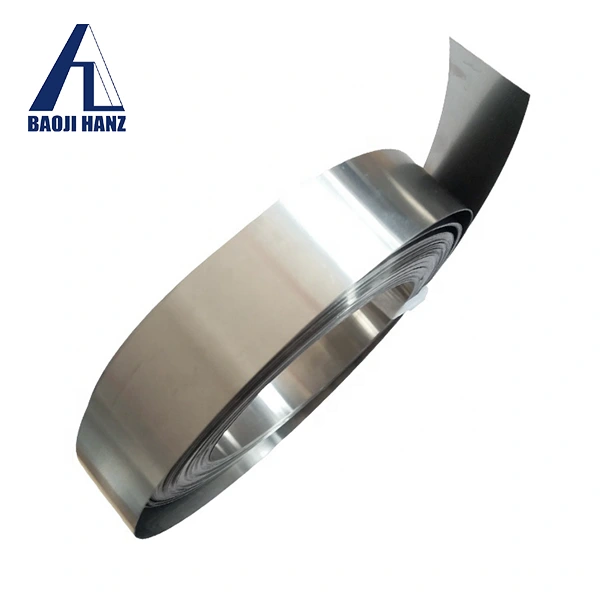

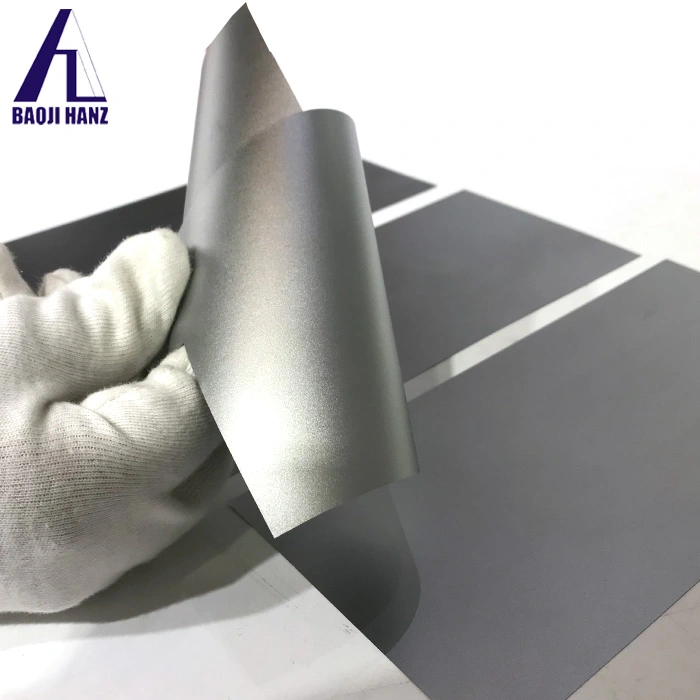

| Shape | Round, Flat, or Custom |

| Surface Condition | Bright, Polished, Oxidized |

| Length | Customizable |

| Tolerance | ±0.005mm |

| Delivery Condition | Annealed or Cold Worked |

Chemical Composition

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 55 - 57 |

| Titanium (Ti) | 43 - 45 |

| Others | < 0.05 |

Application Areas

It finds extensive use in numerous industries due to its exceptional shape memory effect and superelasticity. Some key application areas include:

- Medical Industry: Nitinol wire is widely used in medical devices such as stents, guidewires, orthodontic archwires, and other surgical instruments due to its biocompatibility and ability to return to its original shape after deformation.

- Aerospace: In aerospace engineering, It is employed in actuators and deployable systems that require high flexibility and strength under extreme conditions.

- Robotics and Automation: The superelastic nature of Nitinol wire makes it a valuable component in robotics, where it enables the development of flexible and responsive mechanisms, such as artificial muscles and sensors.

- Consumer Electronics: Nitinol wire is used in mobile devices and other electronics that benefit from its ability to adapt and respond to changes in temperature or force.

- Eyewear: The wire is often used in the frames of eyeglasses, allowing them to withstand bending and shaping while returning to their original form.

Features

- Shape Memory: Nickel Titanium wire can return to its original shape after being deformed when heated.

- Superelasticity: It can undergo significant strains and return to its original form without permanent deformation, making it ideal for applications that require high flexibility.

- Biocompatibility: Nitinol wire is highly resistant to corrosion and is well-suited for medical implants.

- Durability: With exceptional fatigue resistance, the wire can withstand repeated stress and strain without degradation in performance.

Why Choose Us

Baoji Hanz Metal Material Co., Ltd. is a trusted leader in the production of it. Here's why you should choose us:

- High-Quality Materials: We source the finest raw materials to produce it that meets international standards.

- Large Inventory: We maintain a large stock of Nitinol wire in various sizes and specifications, ready for quick delivery.

- Customized Solutions: Our team can manufacture wire to your specific needs, whether it’s for medical, industrial, or commercial applications.

- Certified Products: They come with complete certifications, ensuring compliance with industry standards.

- Fast Delivery: With efficient production and logistics systems in place, we can deliver your orders promptly, no matter where you are in the world.

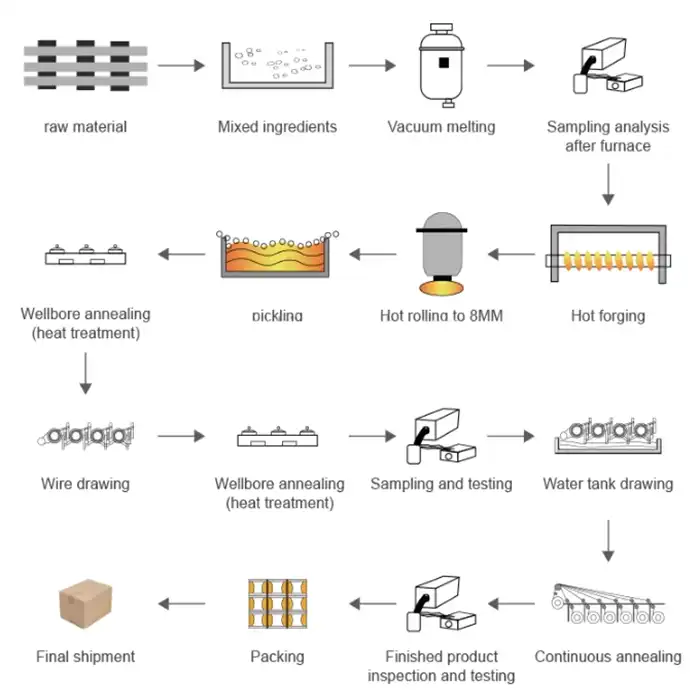

Production Technology

Our nickel titanium wire production involves state-of-the-art technologies, including advanced alloy melting, wire drawing, and heat treatment processes. We utilize vacuum arc remelting (VAR) and electron beam melting (EBM) to ensure the highest purity and homogeneity of the material. Precision drawing techniques are employed to achieve the desired diameter and surface finish, while stringent heat treatments ensure the wire exhibits optimal shape memory and superelastic properties.

Quality Control

Quality is our top priority at Baoji Hanz Metal Material Co., Ltd. Every batch of it undergoes rigorous quality control procedures, including chemical composition analysis, mechanical testing, and fatigue testing. Our in-house laboratory is equipped with cutting-edge testing equipment to ensure that our products meet and exceed customer expectations for performance and reliability.

Company and equipment

Production process

Transportation

FAQ

Q: What is the delivery time for them?

A: Delivery times vary based on order size and customization needs, but we typically ship within 7-14 days after confirming your order.

Q: Can the wire be customized for specific applications?

A: Yes, we offer custom solutions based on your requirements, including specific diameters, lengths, and surface finishes.

Q: What certifications do your products have?

A: They are certified according to international standards such as ISO 9001, CE, and ASTM.

Contact Us

Baoji Hanz Metal Material Co., Ltd. is a professional nickel titanium wire manufacturer and supplier with a factory, large inventory, complete certificates, and fast delivery. If you are looking for high-quality it, please feel free to contact us at:hztech05@hanztech.cn.

_1729339138670.webp)

_1729339137741.webp)

_1729339137981.webp)

_1729339137931.webp)

_1729339137909.webp)

_1729339137886.webp)

.webp)

.webp)

.webp)