Product Details :

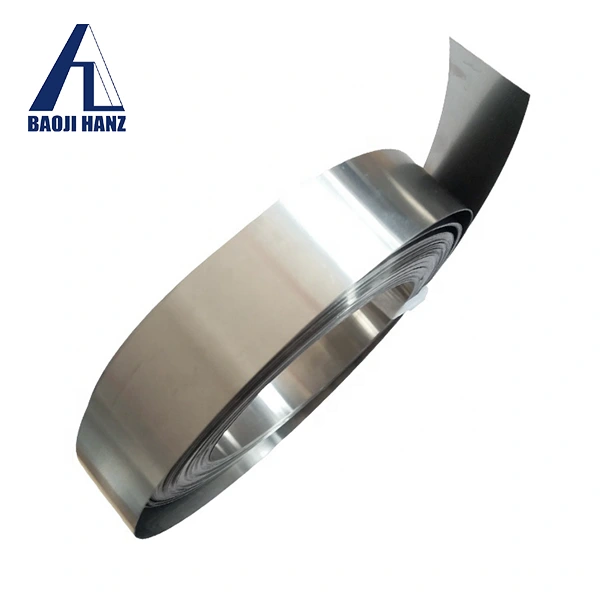

Our Nitinol Wire Superelast is a revolutionary product crafted from a unique nickel-titanium alloy renowned for its exceptional superelastic properties. With its remarkable ability to recover its original shape even after being subjected to significant deformation, our Nitinol Wire Superelast offers unparalleled performance across various applications. Whether in medical devices, automotive components, or aerospace engineering, this cutting-edge material promises reliability and durability like never before.

Specifications:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

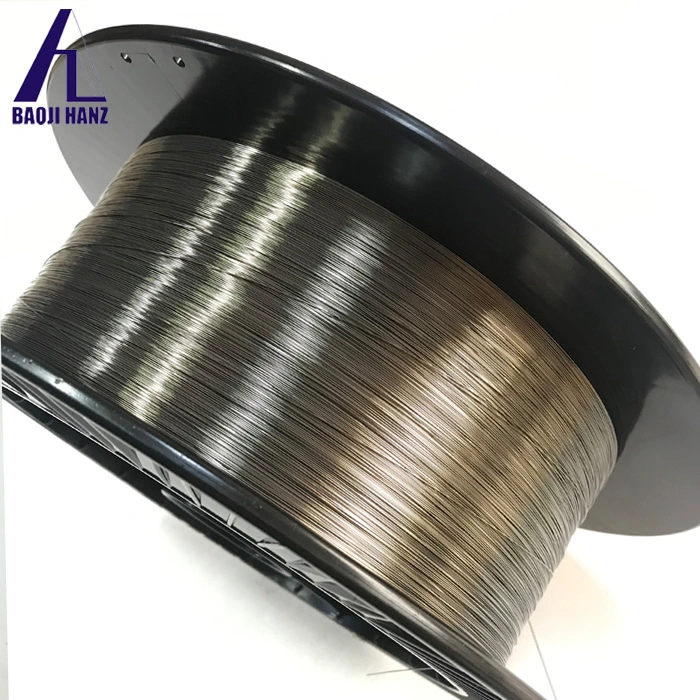

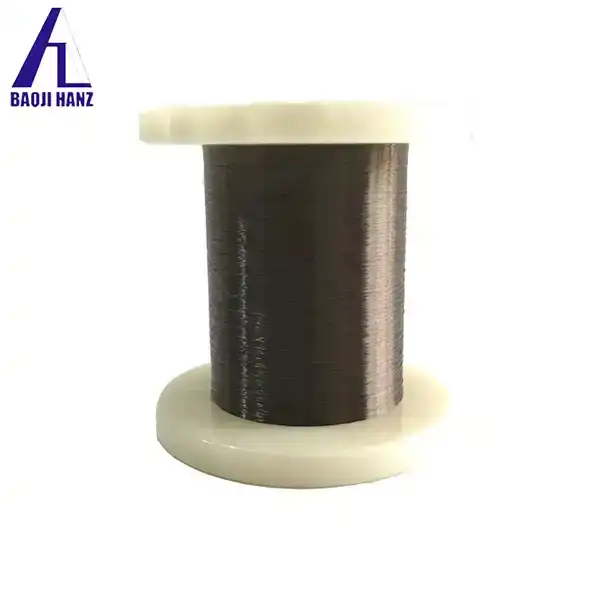

| Color | Black, brown, brown, blue, bright |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Strength | 980 Mpa |

| Processing Service | Bending, Welding, Decoiling |

| Wire Gauge | 0.02mm min |

| Tensile strength | 980 Mpa |

| Feature | Superelastic |

| Supply Status | Full annealed |

| Modulus of elasticity | Austenite 83 Gpa |

| The Max recovery stress | 185 MPa |

| Standard | ASTM F2063, Q/XB1516 |

| Certificate | ISO9001:2015 |

| Application | Guide wires Shape set parts ,Orthodontic Files .Arch wire . fishing wire .bra frames wire .glasses wire .spring wire |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| The production certification | ||||||

| Specification (mm) | Nitinol Superelastic wire | Typical Medical industry Application | ||||

| UTS (Mpa) | Elongation % | UpperPlateau Stress Mpa | Permanent Set after 6% strain % | Active AF | ||

| 0.1-0.3mm | ≥1100 | ≥15 | ≥480 | <0.5 | Subzero20~100 | Guide wires Shape set parts, orthodontic files, arch wire, fishing wire, bra frames wire, glasses wire,spring wire |

| 0.3~0.6mm | ≥920 | ≥15 | ≥440 | <0.5 | ||

| 0.6~3.0mm | ≥850 | ≥15 | ≥440 | <0.5 | ||

|

|

Application Areas :

Nitinol Wire Superelast, with its momentous flexibility, has laid down a good foundation for itself as a vital material in a different range of ventures, because of its unrivaled mix of properties. Its biocompatibility and superelasticity settle on it a go-to decision in the clinical field, where patient solace and treatment viability are of most extreme significance.

In orthodontics, Nitinol Wire Superelast is utilized to create supports that are more agreeable for patients as well as additional compelling in step by step adjusting teeth. The material's capacity to get back to its unique shape in the wake of being twisted makes it ideal for orthodontic applications, where reliable strain is expected overstretched periods. Additionally, in the domain of stents and guidewires, Nitinol Wire Superelast's adaptability and flexibility consider negligibly obtrusive methods, diminishing patient distress and recuperation time.

Careful instruments produced using Nitinol Wire Superelast additionally benefit from its extraordinary properties. The material's capacity to keep up with its shape and endure rehashed use without long-lasting misshapening settles on it a brilliant decision for accuracy instruments that are liable to elevated degrees of stress during a medical procedure.

The auto business has additionally perceived the worth of Nitinol Wire Superelast, using it in different parts like actuators, sensors, and fuel infusion frameworks. The lightweight idea of the material adds to further developed vehicle execution and eco-friendliness, while its strength guarantees that it can endure the afflictions of auto use. The material's protection from mileage, alongside its capacity to keep up with usefulness under a great many temperatures, pursues it a solid decision for parts that are basic to a vehicle's activity.

In the aviation area, medical memory shape nitinol wire's capacity to endure outrageous circumstances while keeping up with exact usefulness is profoundly esteemed. Deployable designs in rocket and satellites frequently consolidate the material because of its shape memory properties, permitting them to spread out or change shape upon openness to warm without the requirement for complex mechanical frameworks. Actuators and damping frameworks in aviation applications likewise benefit from Nitinol Wire Superelast's flexibility and protection from weakness, guaranteeing that they can work dependably in the requesting conditions of room and high-elevation flight.

Features:

- Exceptional superelasticity

- Customizable dimensions

- Superior tensile strength

- Biocompatible and corrosion-resistant

- Wide temperature range compatibility

Production Technology:

Our medical memory shape nitinol wire is manufactured using state-of-the-art processes that ensure precise control over its composition, microstructure, and mechanical properties. Through a combination of vacuum melting, hot working, and shape-setting techniques, we achieve consistent quality and performance in every batch.

Quality Control:

Stringent quality control measures are implemented throughout the production process, from raw material sourcing to final product inspection. Our dedicated team of experts conducts comprehensive tests to verify mechanical properties, dimensional accuracy, and surface finish, ensuring that only the highest quality Nitinol Wire Superelast reaches our customers.

FAQs:

-

What is Nitinol Wire Superelast? Nitinol wire super elast is a nickel-titanium alloy known for its exceptional superelastic properties, making it ideal for various applications requiring flexibility and resilience.

-

What are the application areas of Nitinol Wire Superelast? It finds extensive use in medical devices, automotive components, aerospace engineering, and more.

-

Can the dimensions of Nitinol Wire Superelast be customized? Yes, we offer customizable dimensions to meet the specific requirements of our customers.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is a leading manufacturer and supplier of nitinol wire super elast. With our advanced production facilities, extensive inventory, and complete certifications, we guarantee fast and reliable delivery to our global clientele. For inquiries or orders, please contact us at baojihanz-niti@hanztech.cn.

Send Inquiry