Do nitinol guide wires improve surgery outcomes?

2024-08-24 20:07:55

Nitinol guide wires, known for their unique combination of flexibility, strength, and biocompatibility, have become increasingly popular in various medical procedures. This article delves into how these advanced tools impact surgical outcomes, addressing related high-interest questions along the way.

How Do Nitinol Guide Wires Enhance Precision in Medical Procedures?

Nitinol guide wires have revolutionized the precision of medical procedures by offering superior flexibility and maneuverability. Traditional guide wires made from stainless steel often lack the flexibility required for complex surgeries. Nitinol, an alloy of nickel and titanium, is known for its shape memory and superelastic properties, which allow it to return to a pre-defined shape after deformation. This feature is particularly valuable in procedures such as endovascular surgeries, where the guide wire needs to navigate through intricate and often tortuous anatomical pathways.

Research and clinical experience have shown that the enhanced maneuverability of nitinol guide wires can lead to more precise placement of stents, catheters, and other medical devices. This precision minimizes the risk of damage to surrounding tissues and improves the overall efficacy of the procedure. Studies have demonstrated that the use of nitinol guide wires can reduce the incidence of procedural complications and improve patient outcomes.

What Are the Advantages of Using Nitinol Guide Wires Over Traditional Materials?

Nitinol guide wires offer several advantages over traditional materials like stainless steel. One of the primary benefits is their superior flexibility, which allows them to bend and navigate through complex vascular structures without kinking or breaking. This flexibility is crucial for achieving accurate placement of medical devices in challenging anatomical locations.

Moreover, nitinol’s superelastic properties enable guide wires to return to their original shape after significant deformation. This characteristic not only enhances their durability but also reduces the risk of wire failure during procedures. Additionally, nitinol’s biocompatibility minimizes the risk of adverse reactions when in contact with bodily fluids and tissues, contributing to better overall safety.

In comparison, stainless steel guide wires, while sturdy, often lack the flexibility and biocompatibility of nitinol wires. This limitation can lead to more frequent complications and a higher likelihood of needing to replace or reposition the wire during surgery.

How Do Nitinol Guide Wires Impact Patient Recovery and Procedure Success Rates?

The impact of nitinol guide wires on patient recovery and procedure success rates is a critical consideration for both medical professionals and patients. Enhanced precision and reduced complication rates, thanks to the advanced properties of nitinol guide wires, often translate into better surgical outcomes and faster recovery times.

Several studies have indicated that procedures performed with nitinol guide wires tend to have lower complication rates and improved success rates compared to those using traditional guide wires. This improvement is attributed to the guide wires’ ability to navigate complex anatomical structures more effectively and reduce the likelihood of damage to surrounding tissues.

Faster recovery times can be attributed to fewer procedural complications and less trauma to the patient’s body. The precision of nitinol guide wires helps in achieving optimal device placement, which can lead to fewer follow-up interventions and a smoother recovery process.

Conclusion

Nitinol guide wires represent a significant advancement in medical technology, offering numerous benefits over traditional materials. Their flexibility, durability, and biocompatibility contribute to enhanced precision, reduced complication rates, and improved patient outcomes. As medical technology continues to evolve, the role of advanced materials like nitinol in improving surgical outcomes becomes increasingly important.

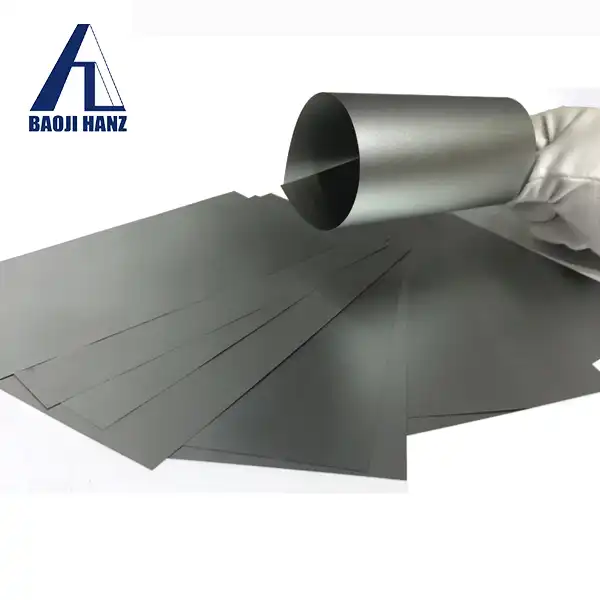

Baoji Hanz Metal Material Co., Ltd. is at the forefront of this technological advancement. Established on November 15, 2017, in the Baoji Titanium Valley Nonferrous Metals Base in China, the company specializes in producing high-quality nitinol shape memory alloys, superelastic nitinol alloys, and nickel-titanium alloys. With a complete set of sophisticated production and processing equipment, the company is committed to leading technology, excellent quality, and stable development. Baoji Hanz Metal Material Co., Ltd. continuously strives to convert scientific research results into practical applications and expand the frontiers of material science.

For more information on how our products can enhance your surgical outcomes, please contact us at baojihanz-niti@hanztech.cn. We look forward to collaborating with professionals from all fields to create a better future through innovative technology.

.webp)