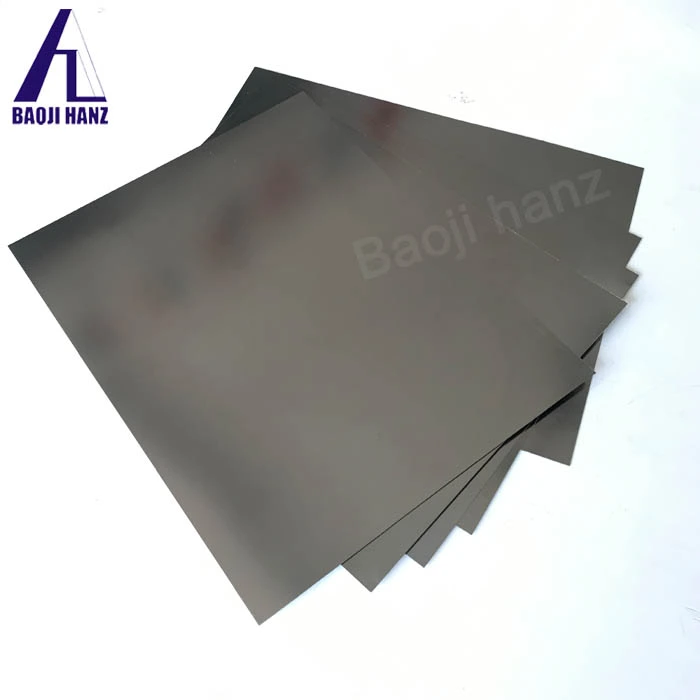

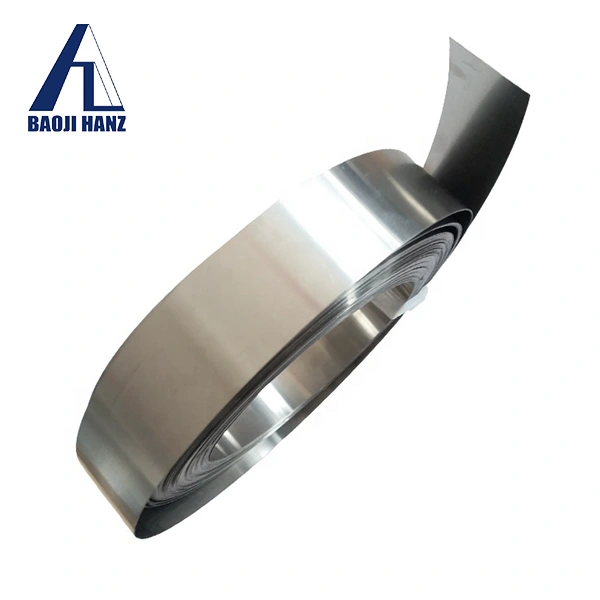

Product Details :

ASTM F2063 superelastic nitinol foil is a determination standard laid out by the American Culture for Testing and Materials (ASTM) that explicitly relates to the products. This standard blueprints the necessities and attributes of it, guaranteeing consistency and quality in its creation and use.

It otherwises called shape memory combination foil, is a particular type of Nitinol that displays surprising mechanical properties, including superelasticity and shape memory impact. This remarkable material can go through enormous disfigurements and return to its unique shape when exposed to explicit boosts, for example, temperature changes. This property makes it ideal for applications where exact and controlled misshapening is required, like in clinical gadgets, actuators, and aviation parts.

The superelastic nitinol foil sets prerequisites for different properties, including arrangement, mechanical properties, layered resiliences, surface completion, and that's just the beginning. By sticking to these determinations, makers can guarantee that the product they produce satisfies the vital quality guidelines for its planned applications.

It tracks down broad use in the clinical field, where it is used in gadgets like stents, guidewires, and orthodontic machines because of its biocompatibility, adaptability, and versatility. In aviation and designing applications, it is esteemed for its high solidarity to-weight proportion, consumption opposition, and weariness obstruction, making it a dependable and strong material for basic parts.

All in all, ASTM F2063 superelastic nitinol foil addresses a state of the art material with exceptional properties that empower imaginative arrangements in different ventures. By meeting the rigid necessities illustrated in the ASTM standard, it guarantees steady execution and unwavering quality, driving headways in innovation and designing applications.

Specifications:

| Place of Origin | Shaanxi, China |

| Brand Name | Baoji hanz |

| Color | Bright surface |

| Materials | Nitinol alloy |

| Density | 6.45 gm/cm3 |

| Ti (Min) | 45% |

| Processing Service | Bending, Welding, Decoiling |

| Feature | Superelastic |

| Supply Status | Full annealed |

| Standard | ASTM F2063-18 |

| Certificate | ISO9001:2015 |

| Application | Cutting Processing Service |

| Chemical element | Af range | Available production Line | Usage | Sample |

| Nickel 55% Titanium 45% | 0℃to 100℃ | Rod&wire,Plate&sheet,Strip&foil | Medical&Industry | On stock (various specification) |

| Nickel 55% +V +Ti | ||||

| Nickel 55% +Fe +Ti | Subzero 30℃ to -5 ℃ | Rod&wire,Plate&sheet | Industry | On stock |

| Nickel 55%+Cr +Ti | (limitedspecification) | |||

| Nickel 55% +Hf +Ti | Above 100C | Ingot | Ingot | Updating |

| Mechanical Properties | ||||

| Thickness | UTS | Elongation | Upper Plateau Stress | Active Af |

| mm | σb MPa (min.) | δ % (min) | σload MPa (min.) | ℃ |

| 0.1 ~ 0.3 | 1100 | 15 | 480 | |

| 0.3 ~ 0.6 | 920 | 15 | 440 | - 20 ~ 100 ℃ |

| 0.6 ~ 6.0 | 850 | 15 | 440 | |

| Tolerance | |

| Nominal Thickness in mm | Permissible Variation from Nominal in mm |

| 6.00 ~ 1.00 | ± 0.05 |

| 1.00 ~ 0.26 | ± 0.03 |

| 0.26 ~ 0.15 | ± 0.02 |

| 0.15 ~ 0.10 | ± 0.01 |

Application Areas :

ASTM F2063 superelastic nitinol foil, fulfilling the particular guidelines set by the American Culture for Testing and Materials (ASTM), tracks down application in a great many ventures and fields because of its one of a kind properties and qualities. A portion of the key application areas of it include:

- Clinical Devices:One of the essential application areas of it is in the clinical field. It is utilized in different clinical gadgets like stents, guidewires, catheters, and orthodontic machines. The superelasticity and biocompatibility of Nitinol foil make it an optimal material for these applications, where exact control, adaptability, and strength are required.

- Actuators and Robotics: It is additionally used in actuators and advanced mechanics because of its shape memory impact and capacity to go through huge disfigurements. It is utilized in applications where controlled and exact developments are fundamental, like in automated grippers, valves, and other impelled frameworks.

- Aviation and Aviation: The high solidarity to-weight proportion, consumption obstruction, and weakness opposition of it make it appropriate for aviation and flight applications. It is utilized in parts like actuators, sensors, and deployable designs, where lightweight yet tough materials are fundamental for ideal execution.

- Auto Industry: In the car area, it is utilized in different applications, including actuators, sensors, and vibration damping frameworks. Its capacity to endure rehashed disfigurements and its versatility make it a significant material for working on the exhibition and productivity of auto parts.

- Hardware and Microtechnology: It is likewise utilized in hardware and microtechnology applications, where its special properties are utilized for making creative gadgets, for example, microactuators, microsensors, and MEMS (Miniature Electro-Mechanical Frameworks) parts.

- Outdoor supplies and Equipment: It is progressively being integrated into outdoor supplies and hardware, for example, golf clubs, tennis rackets, and bike outlines, to upgrade execution, strength, and plan adaptability.

All in all, it is a flexible material with different applications across different enterprises, because of its remarkable mechanical properties and unwavering quality. Its utilization in clinical gadgets, mechanical technology, aviation, car, hardware, and outdoor supplies features the expansive scope of potential outcomes that this exceptional material proposals for development and innovative progression.

Features:

- Superelasticity: Recovers its original shape after deformation.

- Biocompatibility: Suitable for medical implants and devices.

- Lightweight: Ideal for aerospace and automotive applications.

- High Fatigue Resistance: Ensures long-term durability.

- Shape Memory Properties: Retains programmed shapes under varying conditions.

Production Technology:

Our ASTM F2063 nitinol alloy foil is manufactured using advanced techniques such as vacuum arc melting and hot rolling to ensure precise control over material properties and dimensions.

Quality Control:

Severe quality control measures are executed all through the creation interaction to ensure consistence with ASTM F2063 norms. Our committed group conducts intensive investigations, including layered checks, mechanical testing, and compound examination, to guarantee the best guidelines are met.

FAQs:

- What are the typical thicknesses available for it?

- Thicknesses range from 0.005mm to 1.0mm, customizable to specific requirements.

- Is the material suitable for sterilization?

- Yes, our nitinol foil is compatible with common sterilization methods used in medical applications.

- Can the material be soldered or welded?

- Yes, it can be soldered or welded using appropriate techniques compatible with nitinol.

Final Details:

Baoji Hanz Metal Material Co., Ltd. is a leading manufacturer and supplier of ASTM F2063 superelastic nitinol foil. With our state-of-the-art facility, extensive inventory, and complete certifications, we guarantee fast delivery and superior quality. For inquiries or orders, please contact us at baojihanz-niti@hanztech.cn.

Conclusion:

Our product offers unmatched versatility and reliability, making it the preferred choice for demanding applications across diverse industries. Trust Baoji Hanz Metal Material Co., Ltd. for your nitinol needs, and experience the excellence of our products and services.

Send Inquiry

.webp)

.webp)