What is the difference between shape memory nitinol sheets and other shape memory materials?

2024-11-16 23:19:55

Shape memory materials have revolutionized various industries with their unique ability to "remember" and return to their original shape after deformation. Among these materials, shape memory nitinol sheets stand out for their exceptional properties and versatile applications. This blog post delves into the key differences between shape memory nitinol sheets and other shape memory materials, exploring their distinctive characteristics, advantages, and limitations. By understanding these differences, readers will gain valuable insights into the selection and application of shape memory materials for their specific needs, whether in medical devices, aerospace engineering, or cutting-edge technological innovations.

Composition and Structure of Shape Memory Materials

Chemical Composition of Nitinol Sheets

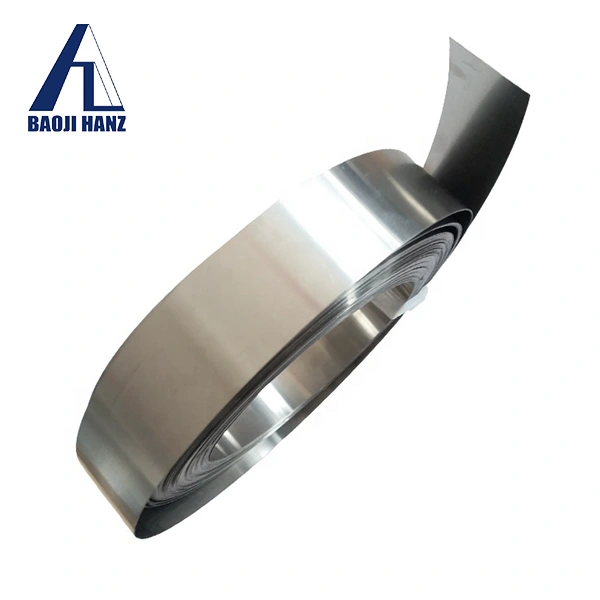

Shape memory nitinol sheets are composed of a near-equiatomic alloy of nickel and titanium. This unique composition gives nitinol its exceptional shape memory and superelastic properties. The precise ratio of nickel to titanium can be adjusted to fine-tune the material's transformation temperatures and mechanical behavior. Typically, the composition ranges from 50% to 51% nickel by atomic percentage, with the remainder being titanium. This delicate balance of elements is crucial for achieving the desired shape memory effect.

Crystal Structure and Phase Transformations

The shape memory effect in nitinol sheets is attributed to a reversible, thermoelastic martensitic transformation. At high temperatures, nitinol exists in an austenite phase with a cubic crystal structure. When cooled below its transformation temperature, it transitions to a monoclinic martensite phase. This phase change is responsible for the material's ability to "remember" its original shape. The transformation can be induced by temperature changes or applied stress, making nitinol sheets highly responsive to external stimuli.

Comparison with Other Shape Memory Alloys

While nitinol is the most widely used shape memory alloy, other materials also exhibit shape memory properties. Copper-based alloys, such as Cu-Zn-Al and Cu-Al-Ni, are alternatives that offer lower cost but generally inferior performance compared to nitinol. Iron-based shape memory alloys, like Fe-Mn-Si, have been developed for potential use in civil engineering applications. However, these materials often have limitations in terms of transformation temperatures, fatigue resistance, or biocompatibility, which make nitinol sheets the preferred choice for many applications.

Unique Properties of Shape Memory Nitinol Sheets

Superelasticity and Pseudoelasticity

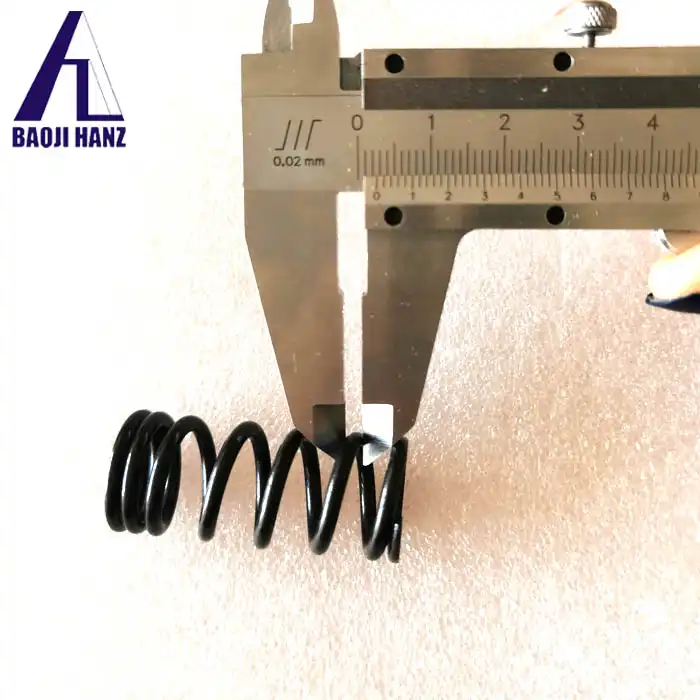

One of the most remarkable properties of shape memory nitinol sheets is their superelasticity, also known as pseudoelasticity. This phenomenon allows nitinol to undergo large deformations and return to its original shape upon unloading, without permanent plastic deformation. Superelasticity occurs when the material is above its austenite finish temperature and is subjected to stress. The stress-induced martensitic transformation enables nitinol sheets to exhibit elastic strains up to 8%, which is significantly higher than conventional metals. This property makes nitinol sheets ideal for applications requiring large, recoverable deformations, such as orthodontic wires and vascular stents.

Shape Memory Effect and Recovery Stress

The shape memory effect is another defining characteristic of nitinol sheets. When deformed in its martensitic state and subsequently heated above its austenite finish temperature, nitinol can recover its original, pre-deformed shape. This process can generate significant recovery stresses, making nitinol sheets useful for actuator applications. The shape memory effect can be one-way or two-way, depending on the material's training. One-way shape memory requires external force to reset the shape, while two-way shape memory allows the material to remember both high and low-temperature shapes.

Biocompatibility and Corrosion Resistance

Nitinol sheets possess excellent biocompatibility, making them suitable for medical implants and devices. The material forms a stable titanium oxide layer on its surface, which provides corrosion resistance and prevents the release of potentially harmful nickel ions. This passive layer also contributes to nitinol's resistance to wear and fatigue. The biocompatibility of nitinol sheets surpasses that of many other shape memory materials, particularly in long-term implant applications where material stability is crucial.

Applications and Performance Comparison

Medical and Dental Applications

Shape memory nitinol sheets have found extensive use in the medical field due to their unique properties and biocompatibility. In cardiovascular applications, nitinol is used to create self-expanding stents that can be compressed for minimally invasive insertion and then expand to their predetermined shape once deployed. Orthodontic archwires made from nitinol provide constant, gentle forces for tooth movement over a wide range of deflections. Other medical applications include guidewires, surgical instruments, and orthopedic implants. The performance of nitinol in these applications is unmatched by other shape memory materials, primarily due to its superelasticity and excellent fatigue resistance.

Aerospace and Engineering Applications

In aerospace and engineering, shape memory nitinol sheets offer innovative solutions for actuation, damping, and adaptive structures. Nitinol-based actuators can provide large displacements and high force outputs in compact designs, making them ideal for deployable structures in spacecraft. The material's high damping capacity is utilized in vibration control systems for aircraft and buildings. Compared to other shape memory alloys, nitinol's wider temperature range of operation and superior fatigue properties make it more suitable for demanding aerospace applications. However, in some high-temperature environments, other shape memory alloys like NiTiHf or NiTiZr may be preferred due to their higher transformation temperatures.

Consumer Products and Smart Materials

The versatility of shape memory nitinol sheets has led to their incorporation in various consumer products and smart materials. Eyeglass frames that can bend without breaking, self-adjusting brassiere underwires, and thermostatic mixing valves are just a few examples of nitinol's consumer applications. In the realm of smart materials, nitinol sheets are used in textile products that can change shape or porosity in response to temperature changes, creating adaptive clothing or architectural fabrics. While other shape memory polymers have made inroads in some of these applications, nitinol's durability, reusability, and precise control over its transformation characteristics often make it the material of choice for high-performance consumer and smart material applications.

Conclusion

Shape memory nitinol sheets offer a unique combination of properties that set them apart from other shape memory materials. Their superelasticity, biocompatibility, and precise control over transformation characteristics make them superior for many applications, particularly in medical and aerospace fields. While other shape memory alloys and polymers have their niches, nitinol's versatility and performance continue to drive innovation across various industries. If you want to get more information about this product, you can contact us at: baojihanz-niti@hanztech.cn.

References

1. Otsuka, K., & Wayman, C. M. (Eds.). (1999). Shape memory materials. Cambridge University Press.

2. Duerig, T., Pelton, A., & Stöckel, D. (1999). An overview of nitinol medical applications. Materials Science and Engineering: A, 273-275, 149-160.

3. Mohd Jani, J., Leary, M., Subic, A., & Gibson, M. A. (2014). A review of shape memory alloy research, applications and opportunities. Materials & Design, 56, 1078-1113.

4. Sun, L., Huang, W. M., Ding, Z., Zhao, Y., Wang, C. C., Purnawali, H., & Tang, C. (2012). Stimulus-responsive shape memory materials: a review. Materials & Design, 33, 577-640.

5. Lagoudas, D. C. (Ed.). (2008). Shape memory alloys: modeling and engineering applications. Springer Science & Business Media.

6. Morgan, N. B. (2004). Medical shape memory alloy applications—the market and its products. Materials Science and Engineering: A, 378(1-2), 16-23.