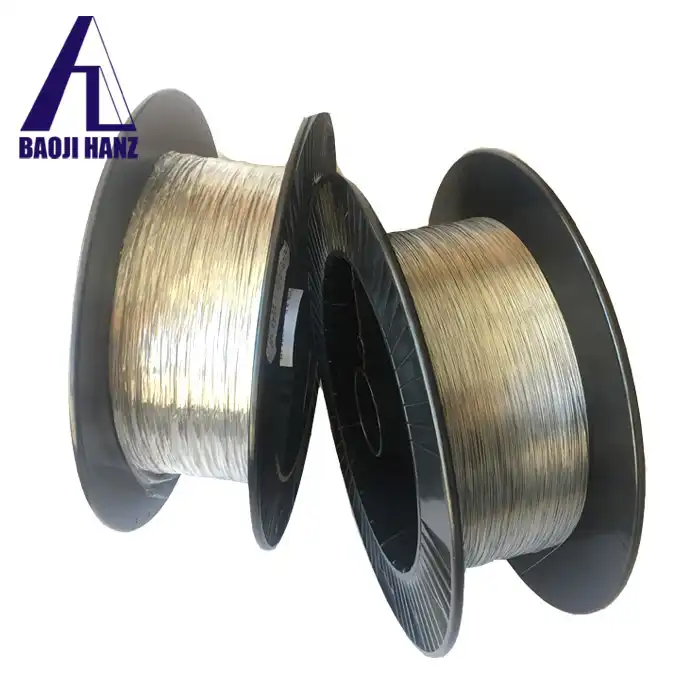

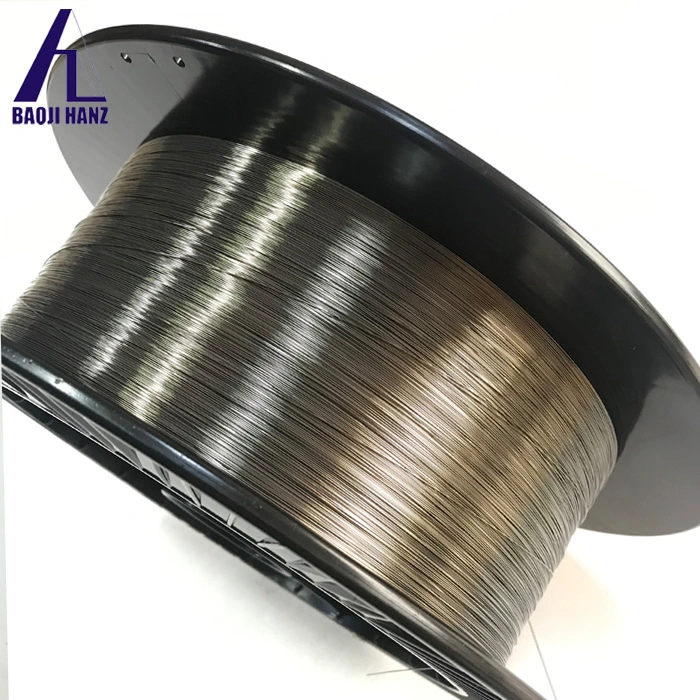

Nitinol shape memory guia nitinol wire

Product introduction

Superelastic shape memory nickel-titanium guide wire product knowledge

Nitinol guide wire

Nickel-titanium guide wire advantage :

Superelasticity: automatically restores to the original state after bending, resisting permanent deformation.

Shape memory: Restore the preset shape at body temperature.

Good flexibility: high bending radius, suitable for complex vascular paths.

Corrosion resistance: Strong biocompatibility, suitable for internal environment.

Fatigue resistance: stable performance under long-term cyclic load.

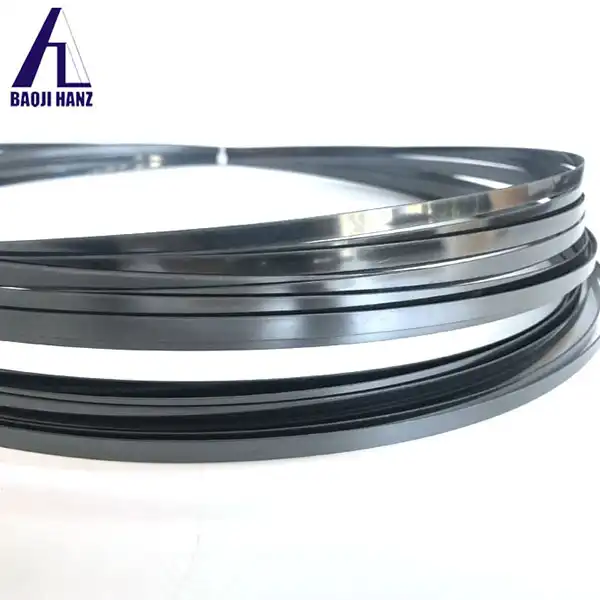

Nickel-titanium guide wire characteristics:

Material: NiTi alloy.

Surface treatment: polished.

Diameter range: 0.1~2mm (medical commonly used 0.014~0.035 inches)

Nickel titanium guide wire Application:

Medical: cardiovascular intervention, neurological intervention, endoscopic guidance, urology.

Industry: minimally invasive instruments, precision instrument guidance, robot flexible transmission.

FAQ

Q: Is nickel-titanium wire allergic?

A: Medical grade NiTi has good biocompatibility and very few people who are allergic to nickel need to be evaluated.

Q: Why more expensive than stainless steel guide wire?

A: High material cost + complex heat treatment process.

Q: Disinfection method?

A: High pressure steam (134℃), ethylene oxide or plasma sterilization.

Q: What if the guide wire breaks?

A: Choose products with high fatigue life to avoid excessive bending during the operation.

Product parameter

| Diameter | 0.1~2mm |

| Surface | mechanical polishing |

| Ti (Min) | 45% |

| Af: | -20℃~100℃ |

| Density | 6.45g/cm3 |

| Material: |

Nitinol Ti-Ni Alloy |

| Operating temperature: | -50℃~150℃ (high temperature model up to 200℃) |

| Certification standards: | ISO 13485 (Medical), ASTM F2063 (Memory alloy materials) |

| MOQ: | 1kg |

Production process

Production process of bidirectional Nickel-titanium guide wire

Material preparation: - Molding: - Heat treatment: - Training process: - Surface treatment: - Test Calibration: - Sorting and Packaging:

Company profile

ABOUT US

Baoji Hanzhen Metal Materials Co., Ltd. is located in China Baoji titanium Valley non-ferrous metal base. The company has a set of precision production and processing equipment, excellent technology, professional sales and after-sales team. Main business: tungsten, molybdenum, Ni-Ti memory alloy, tantalum, niobium and its alloy materials; Industrial furnace, mechanical equipment design, manufacture, production and service. The company has advanced research and development, production, testing equipment. Continuously committed to the conversion of scientific research results and the localization of imported products, we have completed major projects such as the preparation of high-purity metal materials, ultra-large and ultra-thin casting, radiation generation and control materials development, which has broadened new ideas for material purification, processing and new material preparation, and provided new markets and opportunities.

The company will be dedicated to the "leading technology, excellent quality, steady development, win-win cooperation" business philosophy, is willing to work with colleagues from all walks of life to grasp business opportunities, create a better future.

Shipping:

Payment method

We generally accept payment methods for orders: wire transfer, PayPal, Western Union, L/C, et

Why choose us

Contact us

Baoji Hanz Metal Material Co., Ltd.

Gaoxin Avenue, BaoJi city, ShaanXi province China

Tel: 86-917-3258889

Mobile, Whatsapp,Wechat: +8618091719909

Email:baojihanz-niti@hanztech.cn

Send Inquiry

_1740043052871.webp)

.webp)